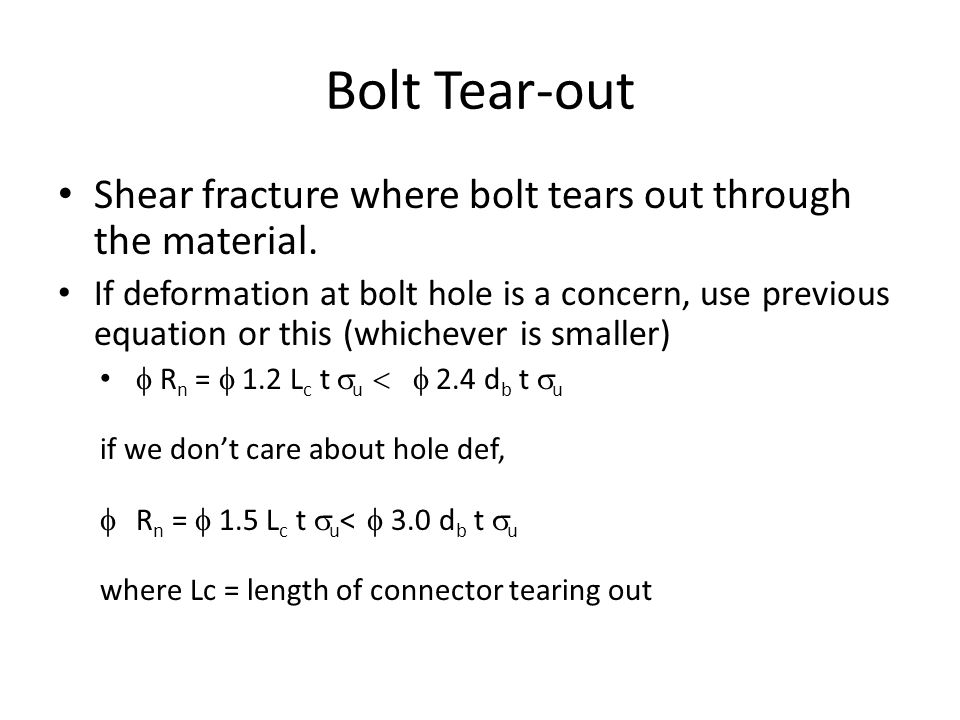

= Shear stress MPa,psi Ft = shear force N, lb A = Throat area of the weld mm2, in2 Reference Stress Where = Reference stress MPa , psi = Shear stress MPa, psi = Coefficient of weld joint Weld Design Menu Normal Stress Where = Normal Stress MPa,psi F = For the tear out limit state the area equals the material thickness, t, times the clear distance in the direction of force of the tear out, L c The area in question is illustrated in Figure 361(b) L c is the minimum such value on your member The stress is some constant (1, 12, or 15 depending on which criteria you use) times F uTear strength is the amount of force needed to rip a particular sampling subject and to continue through it in a vertical axis Typically used for testing of plastic film, plastic sheets and other rubber products, tear strength is calculated by force (in Newtons) divided by thickness (in millimeters, centimeters, inches, etc) Tear strength = F/t

2

How to calculate tear out stress

How to calculate tear out stress- Substituting the numbers into the equation T = 02 * 0375 * 3,1 = 2391 inch pounds or approximately ftlb So a dry SAE Grade 2 bolt should be torqued to approximately ftlb toThe following design resources are for design screws and bolts for the proper torque, stress, strain, preload and other engineering critical design parameters Thread Stress Area Calculator and Equation Bolt Threads, Grade, Bolt Strength, Excel Spreadsheet Calculator, Spreadsheet Calculated per the AISC Ninth Edition

Allowable Bearing Stress Aisc Welding Bonding Fastener Engineering Eng Tips

Tensile stress area A t =π/4 d 0 2 mm 2 shear area A th = 05πd 0 L e mm 2 Shear strength F = T A th kN Tensile stress σ = F / A t MPa wwwtribolog yabccom What's the Difference Between Bearing, Shear, and TearOut Stress?I am having problems finding an accurate formula to calculate the tearout and bearing stress of a 22mm dia pin through a 40mm dia hole, with plate thickness of mm and hole 35mm from plate edge I don't think the standard bearing stress formula is viable because of the difference in holepin dia Its easy if you have access to FEA software

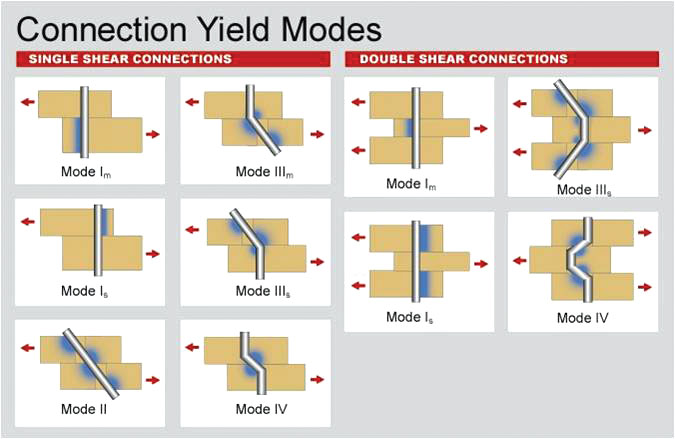

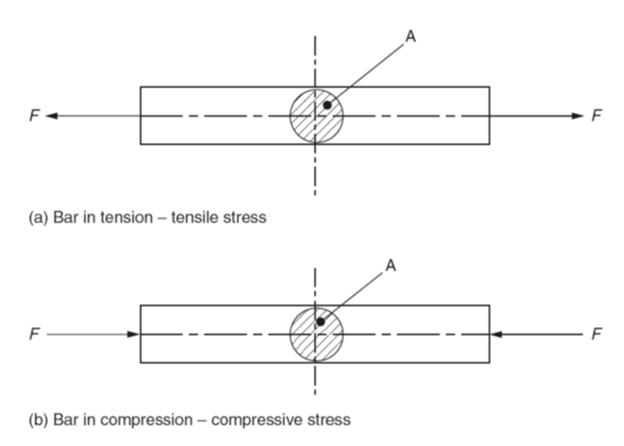

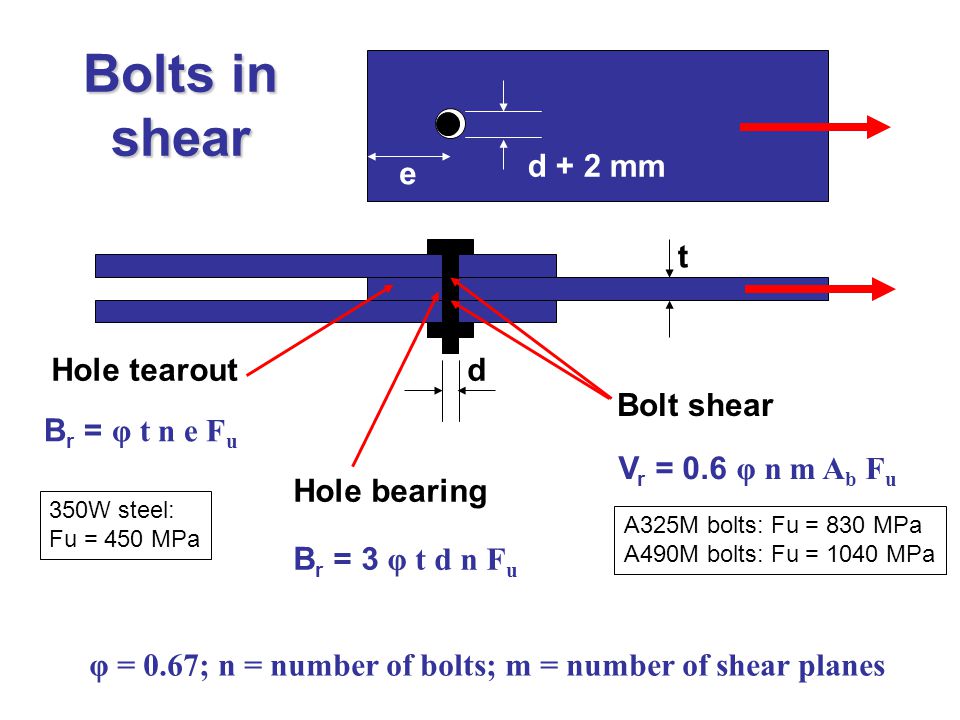

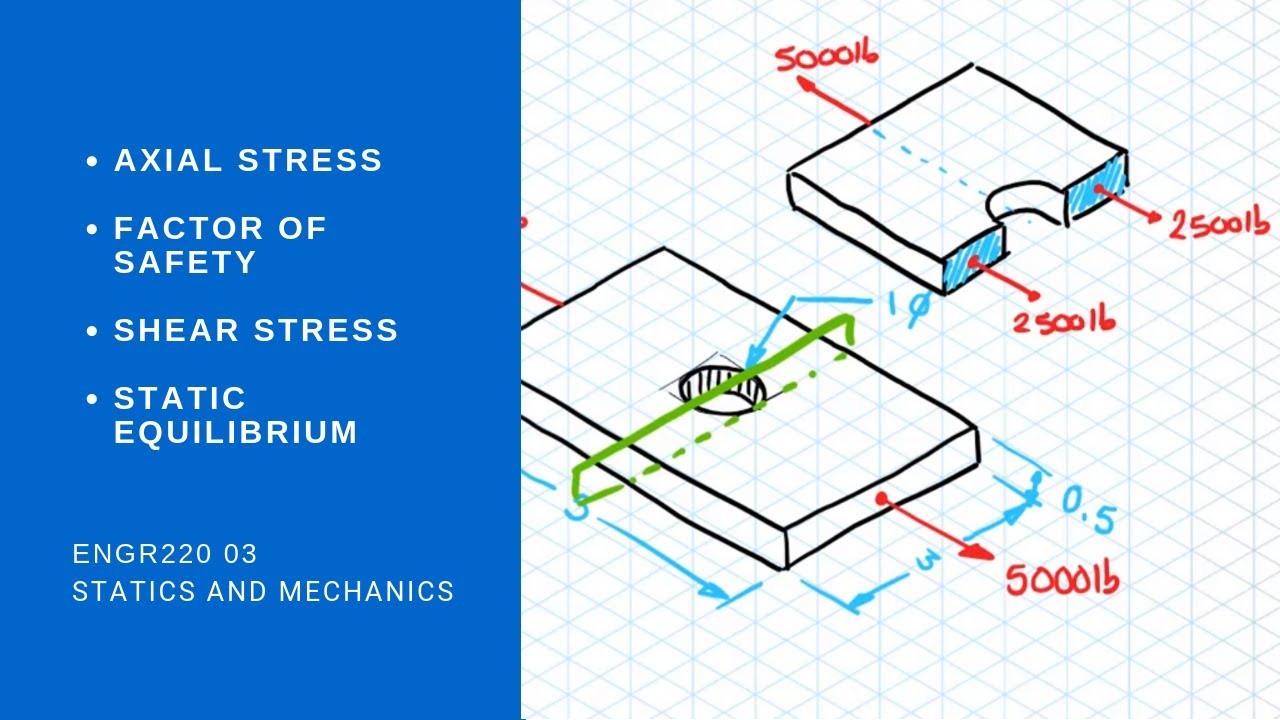

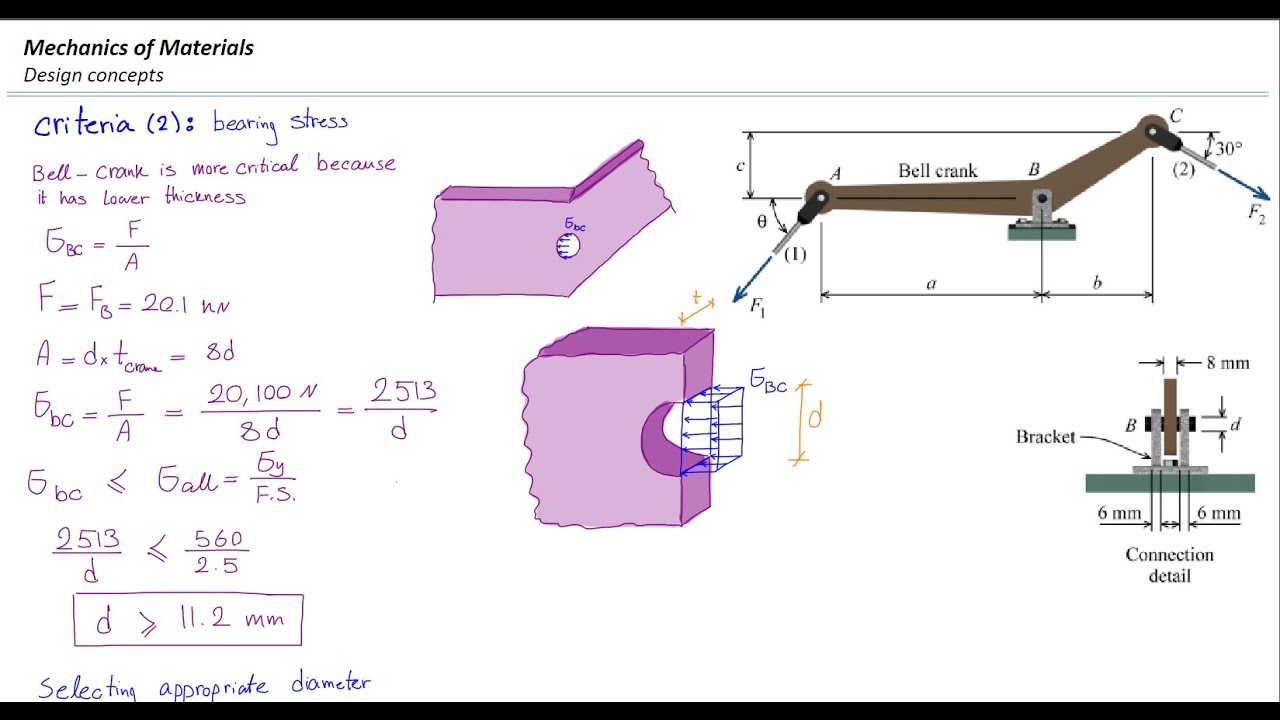

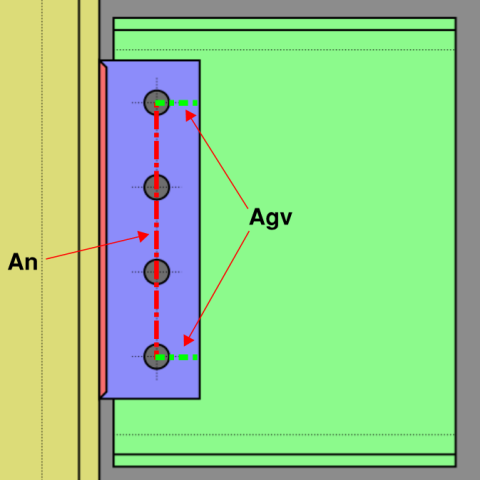

Stress Calculations – Example 1 From statics we can determine F BC = 50 kN = 11,240 lb f (Tension) F AB = 40 kN 92 lb f (Compression) Specifications • Joints are single and double shear connections (frictionless) • The distance from the center of the hole of joint C to the end of the member is 25mm DetermineFor this reason, the tensile stress area is calculated through an empirical formula involving the nominal diameter of the fastener and the thread pitch P = St x As P = tensile load (lbs, N) St = tensile strength (psi, MPa) As = tensile stress area (sq in, sq mm) Applied to a 3/410 x 7" SAE J429 Grade 5 HCS P = ?Connected element is shear tearout as shown below This type of shear tearout can also occur between two holes in the direction of the bearing load Rn = 2 x 06 Fu Lc t = 12 Fu Lc t 5

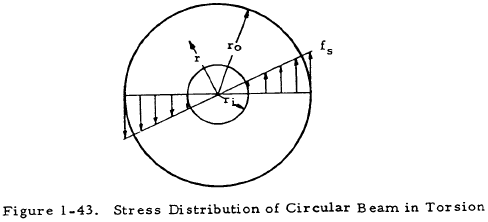

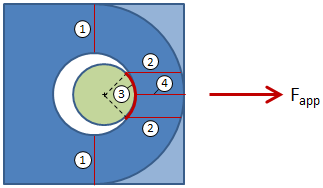

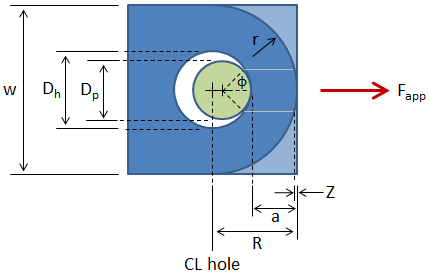

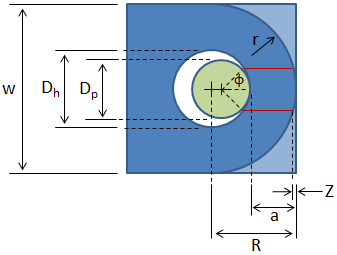

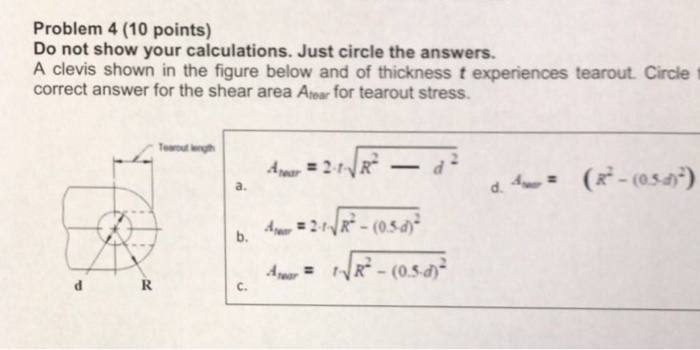

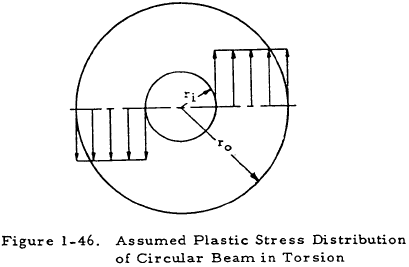

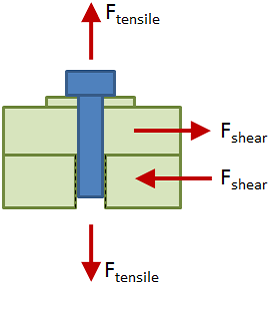

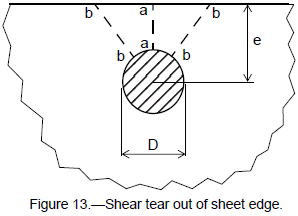

Tearout shear stress is In this formula A=t(RoRi) is approximately and conservatively the area of the dotted crosssection Ro and Ri are the outer and inner radii of the clevis hole Note that there are 4 such areas Shear stresses in beams under bending forces Torsion ofMaximum normal stress when = 0 (or 180) Maximum shearing stress when = 45 (or 135) (opposite directions) Minimum stress = 0, when = 90 Note maximum stresses don't appear on the same angle A P max A P max 2Here is a short introduction into bearing, shear, and tearout stresses in bolted joints and how complex they can be

2

What S The Difference Between Bearing Shear And Tear Out Stress Machine Design

The formula for shearing out of a fixing to the edge of the plate is F= allowable shear stress in plate * 2*e*t where F is the force to cause failure e is distance from fixing centre to edge of plate t is the plate thickness It is normally reccomended that fixings should be at least (15 * "diameter of fixing") away from plate edges regards desertfox4 The tearout strength at the edge for the ½ in plate is 294 kips/bolt 5 The tearout strength at the edge on each of the 3/ 8in plates can be found by prorating the strength of the ½in plate 294(0375/05) = 2 kips/bolt/plate or 44 kips/boltStress occurs on the net section At this stress level, the bolt may not tear from the joint—but for simplicity, the limit state is still referred to as tearout Tearout can occur between a bolt and any edge, whether the edge occurs at the end of the material or at an adjacent bolt hole The Change The change to the 16 Specification is minor Equation J3

2

Beam Torsion Engineering Library

Tear out is when the pin literally rips through the material under load It can also describe the pin tearing a coupon of material from the plate if the hole is too close to the edge of the plate Bearing is a local phenomenon and deals with local deformation of

2

2

2

01 Rivet Design Tearing Crushing Ans Shear Strength Youtube

Structure Magazine Design Of Bolted Connections Per The 15 Nds

Lecture 2 Prob3 Bearing Stress In Washer And Bolt Youtube

Strain Curve For Muscle Stress

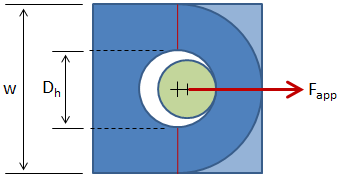

Lug Analysis Mechanicalc

Stress

Stress And Strain Cylindrical Bar Of Cross Sectional Area Engineersfield

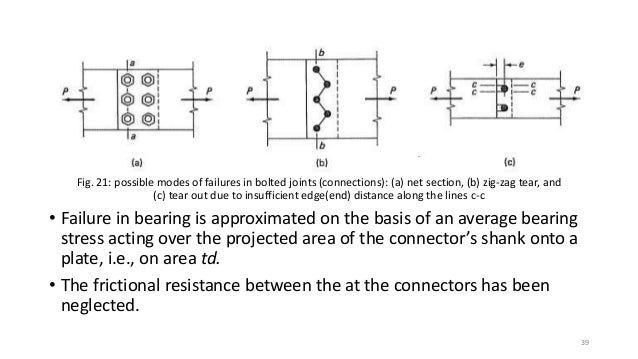

Connection Design Ppt Download

1

2

2

2

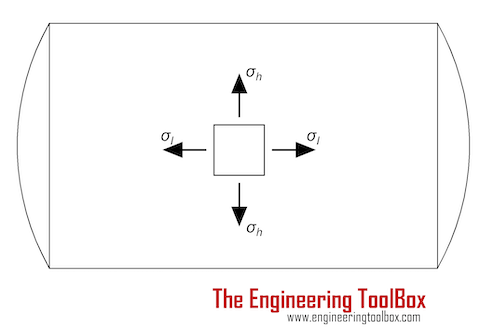

Stress In Thin Walled Cylinders Or Tubes

2

2

Simple Stress Analysis Flat Plate With Hole Physics Forums

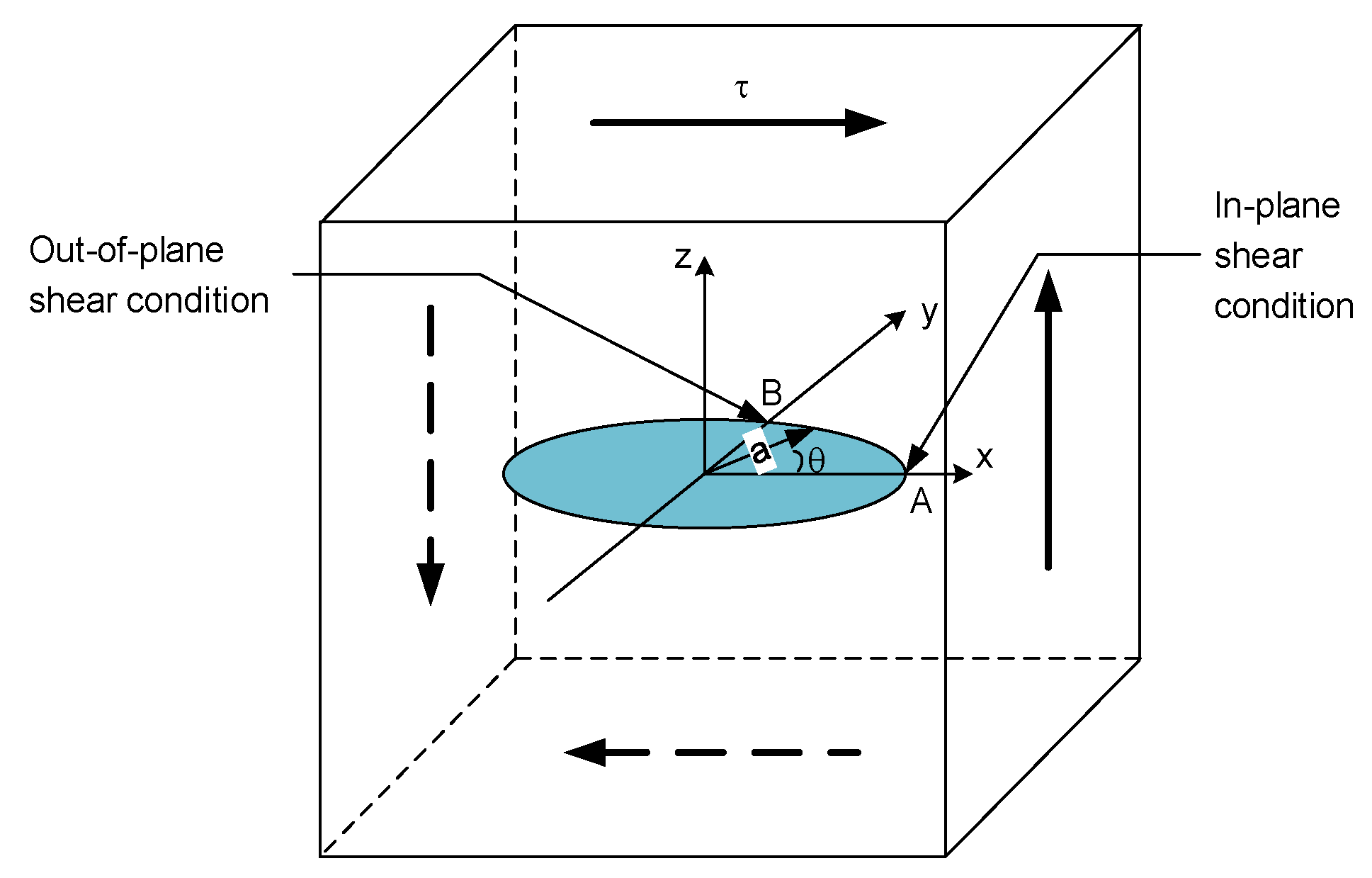

Mechanics Ebook Plane Stress

Lug Analysis Mechanicalc

Lug Analysis Mechanicalc

Example 6 Polygonal Slab With Circular Opening Download Scientific Diagram

2

Axial Stress Bearing Stress Shear Stress Tearout Stress Engr 2 Youtube

Allowable Bearing Stress Aisc Welding Bonding Fastener Engineering Eng Tips

2

2

An Analytical Method For Determining The Load Distribution Of Single Column Multibolt Connection

Simple Stress Analysis Flat Plate With Hole Physics Forums

1

Shear Tearout Of Bolt In Structural Standards As4100 Structural Engineering General Discussion Eng Tips

A 500 B 159 10 6c 159 D 3975 Question 16 The Average Shearing Stress Is The Course Hero

Ship Structur Plats Name Vehicles Structures Beyond Discovery

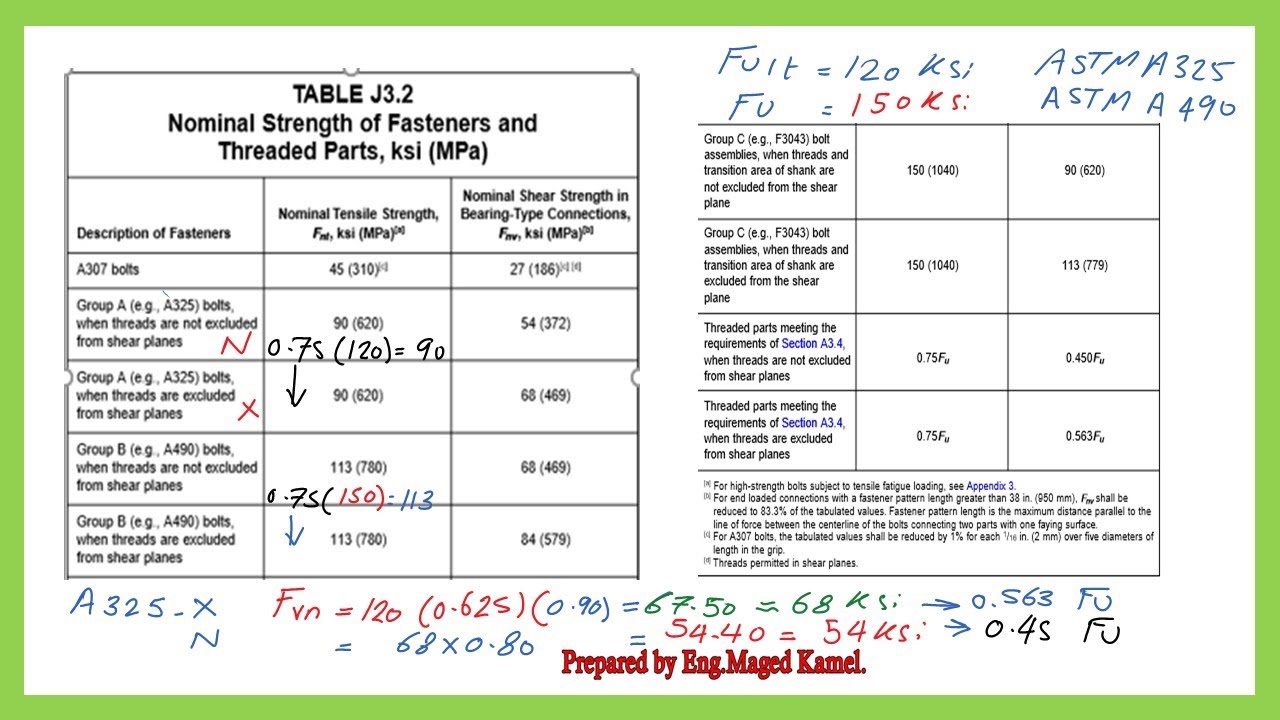

4 Nominal Shear Strength And Bearing Tear Out Made Simple

What S The Difference Between Bearing Shear And Tear Out Stress

2

Lec 4 Prob5 Shear Stress And Bearing Stress In A Bell Crank By Mechanics Of Materials

Lug Analysis Mechanicalc

2

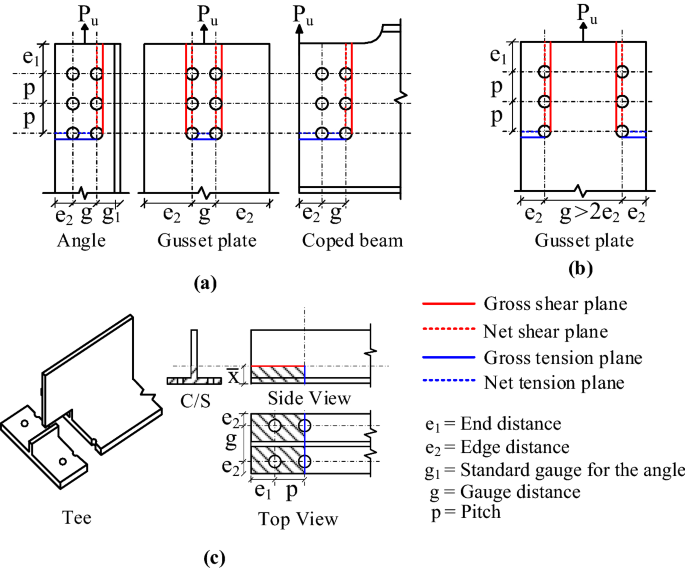

Behaviour Of Block Shear Failure In Different Connections Springerlink

Spot Weld Perpendicular Loading Of Weld Area Stress Equation And Calculation

Screw Thread Calculations Roy Mech

Appendix D Padeye Design Dnv 2 1 Pdf

2

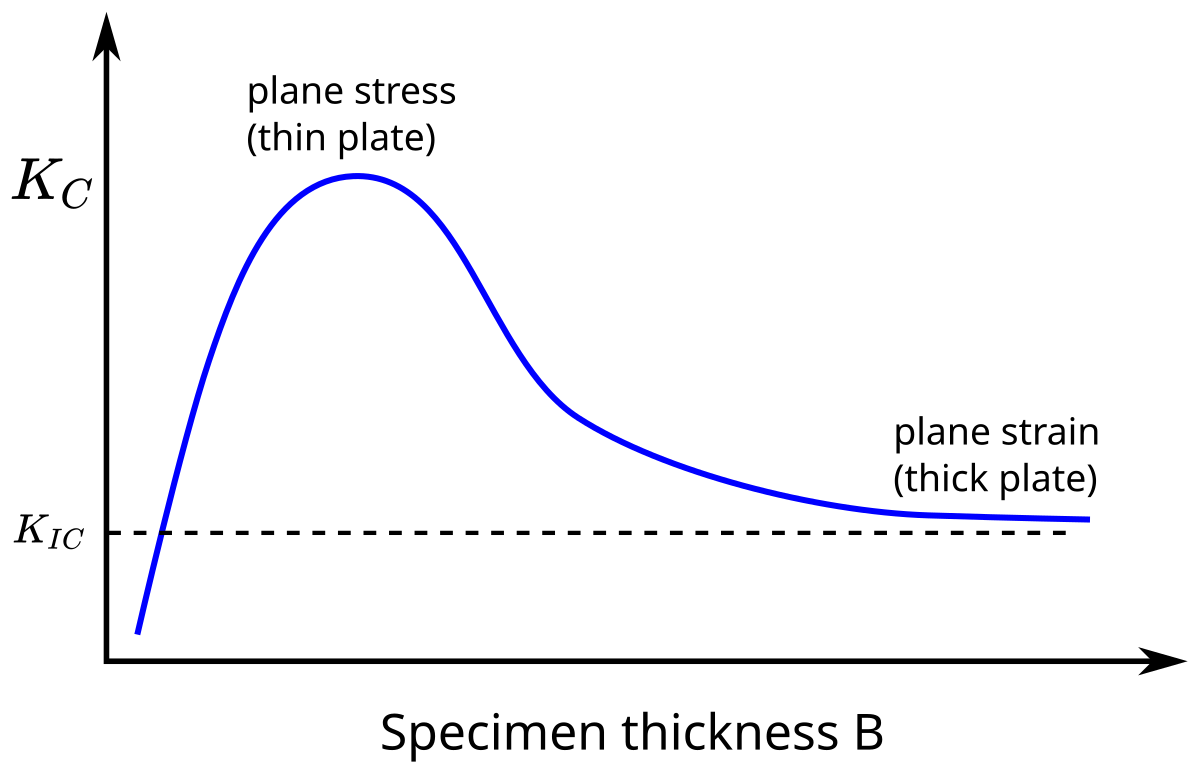

Fracture Toughness Wikipedia

2

Tear Out Capacity Of Steel Plate With Holes Welding Bonding Fastener Engineering Eng Tips

Problem 4 10 Points Do Not Show Your Calculations Chegg Com

2

Bolt Plate Bearing Strength Steel And Concrete Design Youtube

Simple Stress Analysis Flat Plate With Hole Physics Forums

Chapter 12 Riveted Bolted Welded Connections 1 Riveted

2

Plane Stress An Overview Sciencedirect Topics

1

2

Material Checks

Problem 4 10 Points Do Not Show Your Calculations Chegg Com

1

Hoop Stress An Overview Sciencedirect Topics

Failure Modes A Row Shear B Shear Plug Group Tear Out Block Download Scientific Diagram

Mitcalc Design And Strength Check Of Welded Connections

2

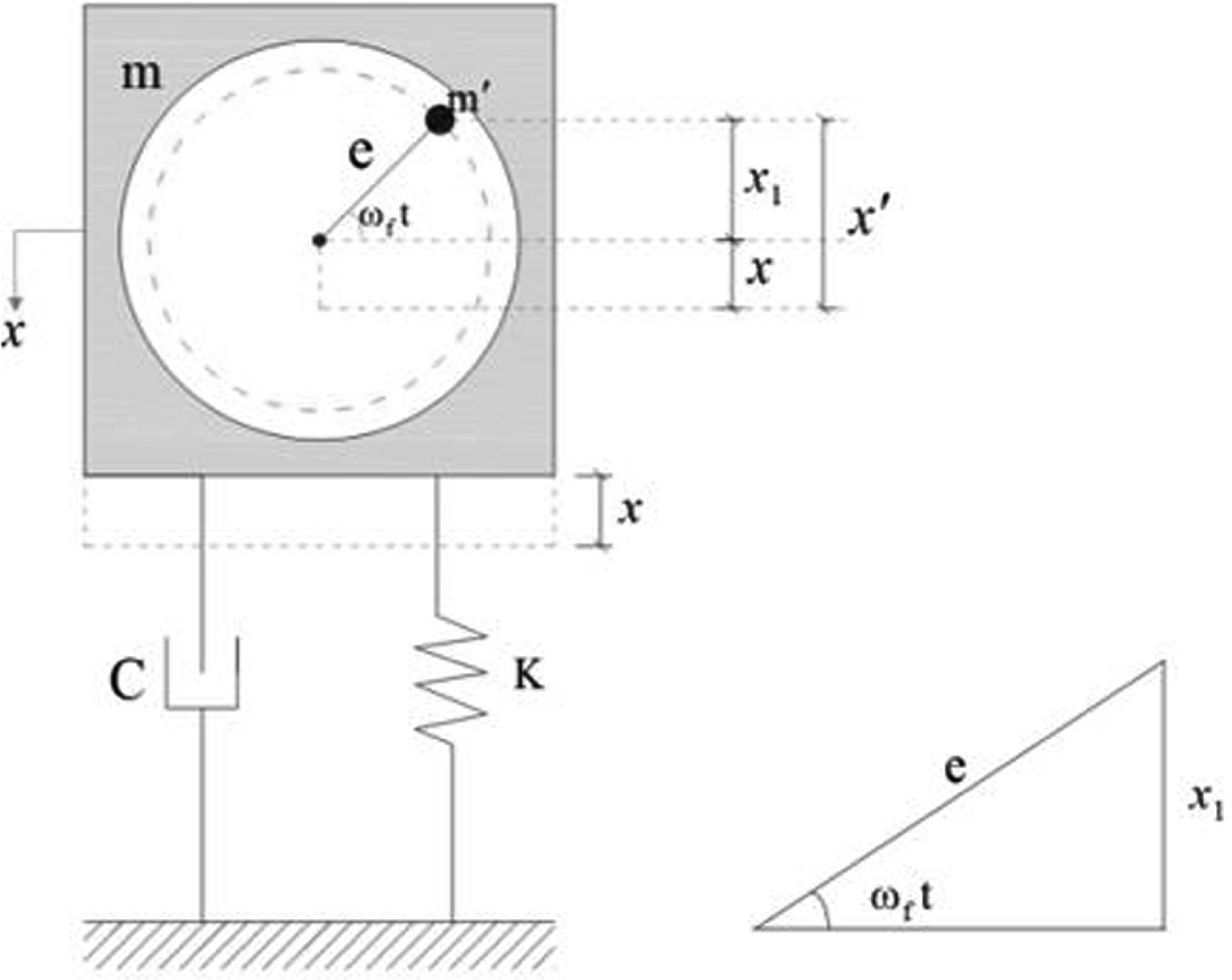

Single Degree Of Freedom Systems Subjected To Various Excitations Springerlink

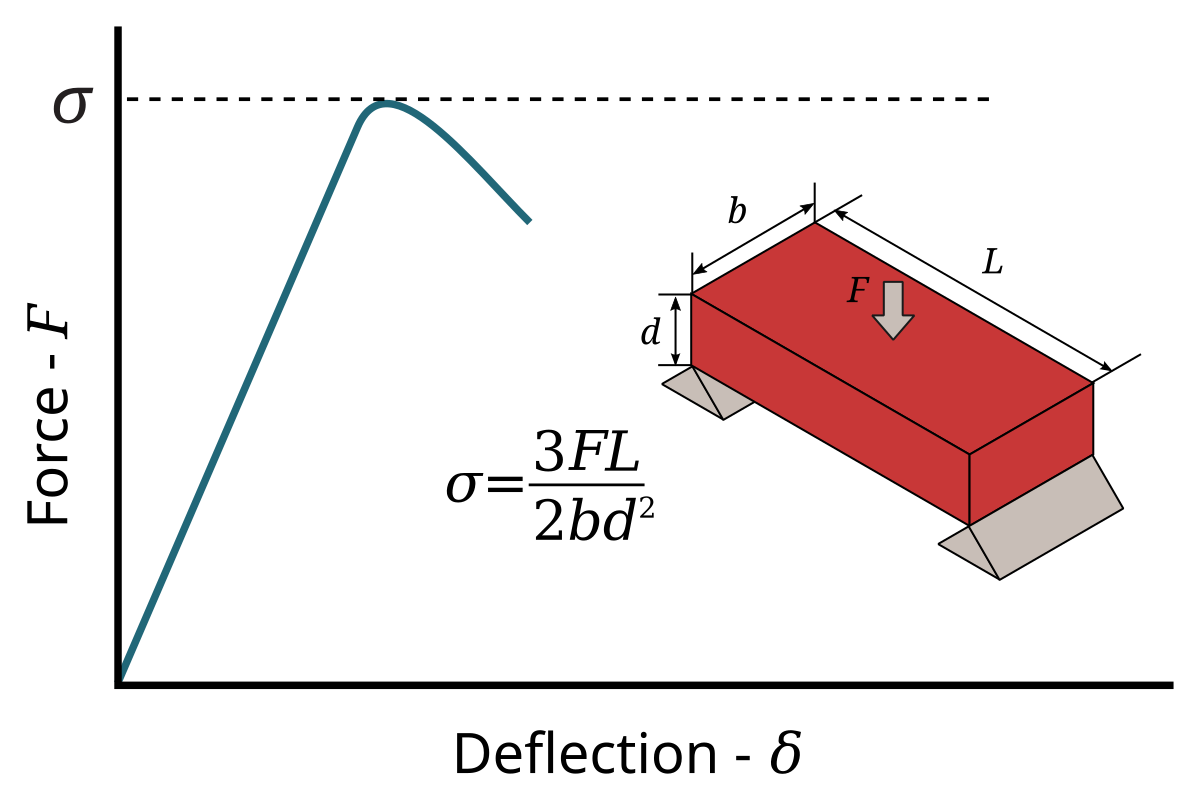

Flexural Strength Wikipedia

Beam Torsion Engineering Library

Review Article Stress In Thin Films And Coatings Current Status Challenges And Prospects Journal Of Vacuum Science Technology A Vol 36 No 2

What Is Tearing Stress What Is The Difference Between Tearing And Bearing Quora

Block Shear

2

Bearing Stress Strength Of Materials Review At Mathalino

What S The Difference Between Bearing Shear And Tear Out Stress Machine Design

Bearing Stress Youtube

4 Nominal Shear Strength And Bearing Tear Out Made Simple

Block Shear Rupture

Combined Bearing And Shear Out Capacity Of Structural Steel Bolted Connections Journal Of Structural Engineering Vol 142 No 11

Shear Tearout Of Bolt In Structural Standards As4100 Structural Engineering General Discussion Eng Tips

4 Nominal Shear Strength And Bearing Tear Out Made Simple

4 Nominal Shear Strength And Bearing Tear Out Made Simple

Simple Stress Analysis Flat Plate With Hole Physics Forums

2

2

Connection Design Ppt Video Online Download

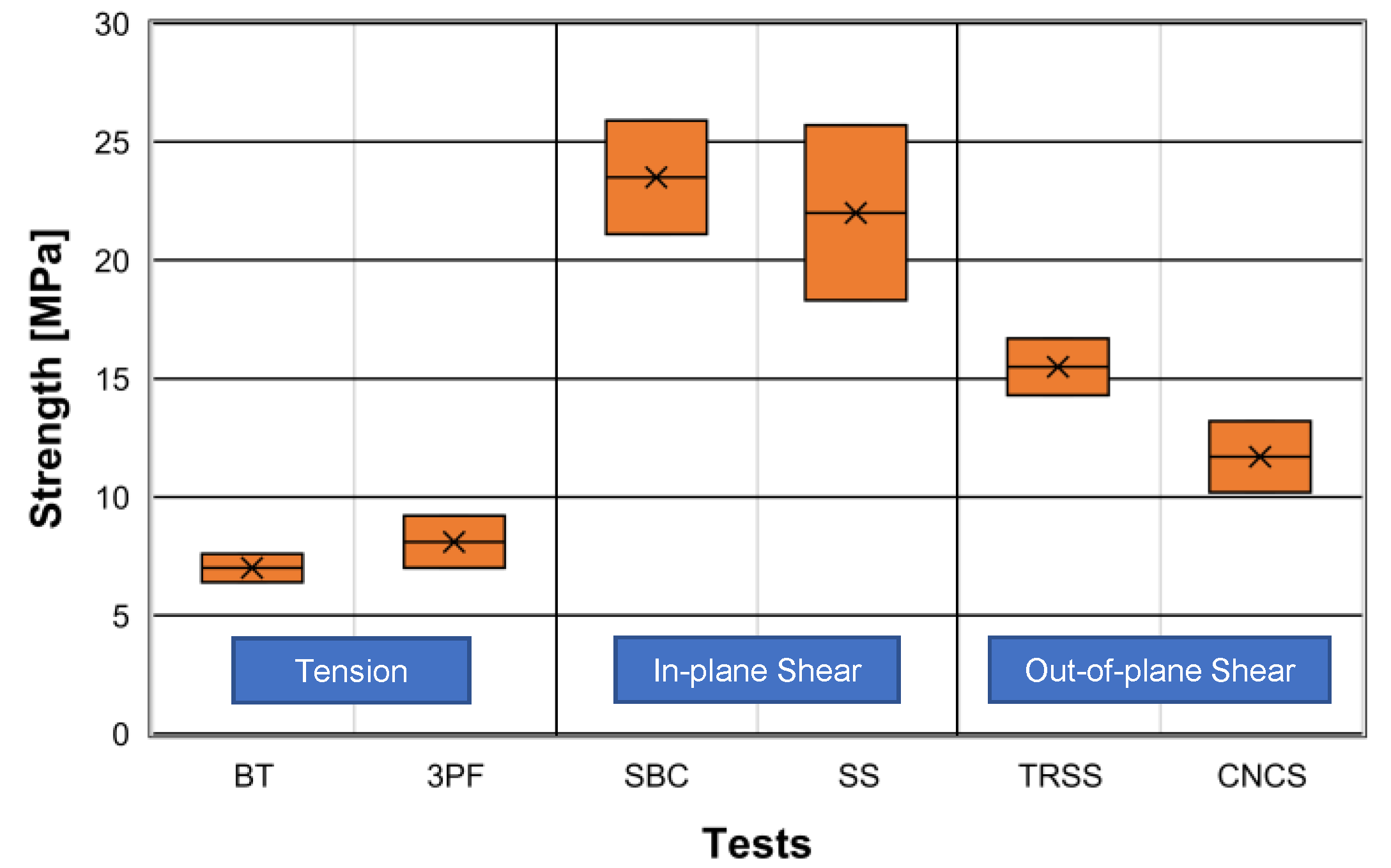

Applied Sciences Free Full Text Experimental Study On Stress Corrosion Index Governing Time Dependent Degradation Of Rock Strength Html

2

Bolted Joint Analysis Calculator Mechanicalc

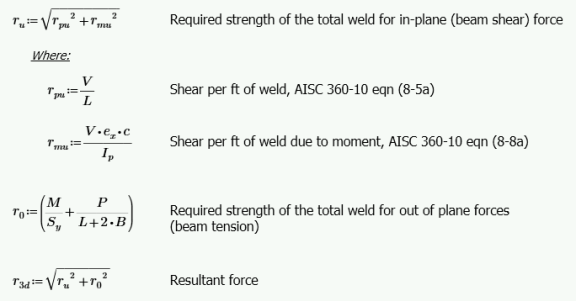

Weld Calculations

4 Nominal Shear Strength And Bearing Tear Out Made Simple

Bearing Stress Of Bolt Or Rod Strength Of Materials Example Problem Solution Youtube

What S The Difference Between Bearing Shear And Tear Out Stress Machine Design

Lug Analysis Mechanicalc

Applied Sciences Free Full Text Experimental Study On Stress Corrosion Index Governing Time Dependent Degradation Of Rock Strength Html

Bolt Bearing

2

What S The Difference Between Bearing Shear And Tear Out Stress Machine Design

2

Chapter 1 Stress Axial Loads And Safety Concepts

Preloaded Joint Analysis Engineering Library

2

0 件のコメント:

コメントを投稿